CNC Bending Sheet Metal

CNC Bending is a commonly used and cost effective manufacturing method used to process sheet metal. Bending machines are typically either a Press Brake or Swing Bending machines.

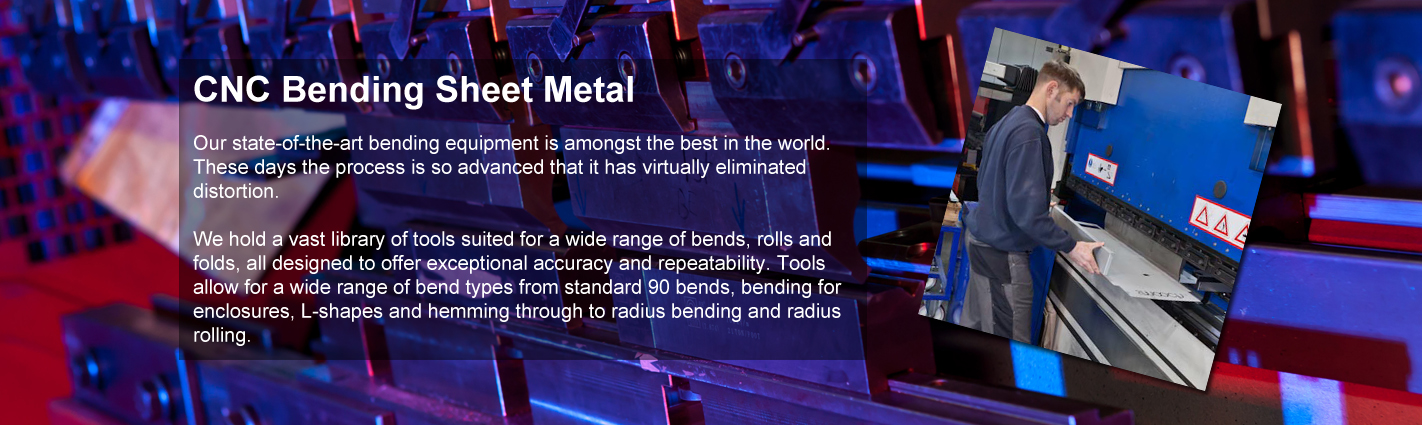

Our CNC Bending presses offer versatility and a variable volume, this ensures every bend is consistent and accurate. This accuracy combined with the precision from laser cut components and the speed from punching, means we are highly capable of large volume fabrication.

Using our experience we work closely with clients to make designs aimed at achieving the best results, both in terms of cost and quality of the finished product. Combined with our state of the art CNC Bending facilities and over 50 years manufacturing experience, we also provide our customers with a competitive edge that other sheet metal bending companies can't.

0115 9269649

0115 9269649 Email Us

Email Us Contact Us

Contact Us